Trouvez le mélangeur le plus adapté à votre marché

Rentabilisez

votre investissement au plus vite en testant vos mélanges

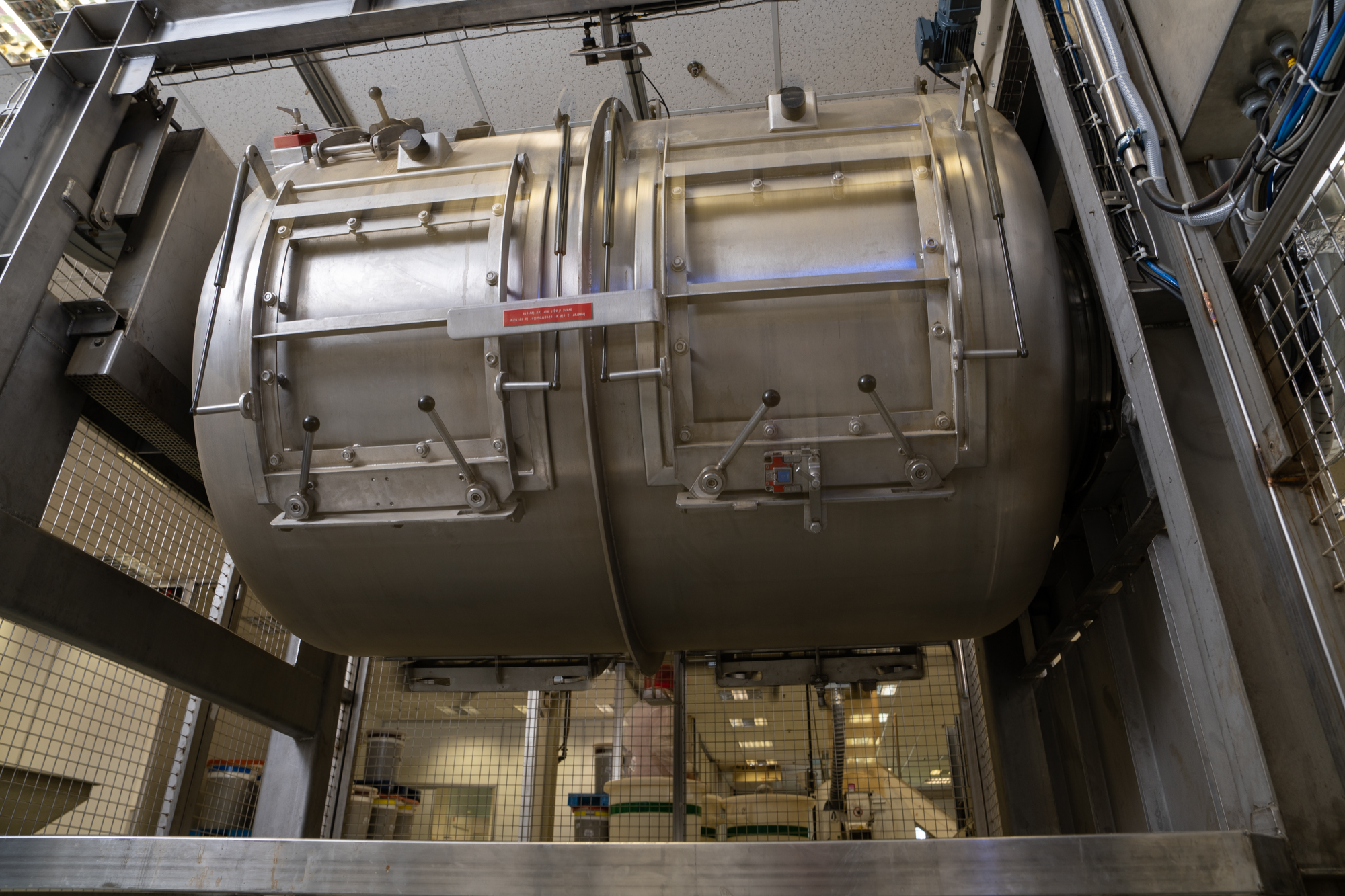

Avant d'investir dans un nouveau mélangeur, vous avez besoin de valider votre recette, votre process, pour vous assurer qu'il est réalisable dans les conditions de rentabilité et de qualité exigées.

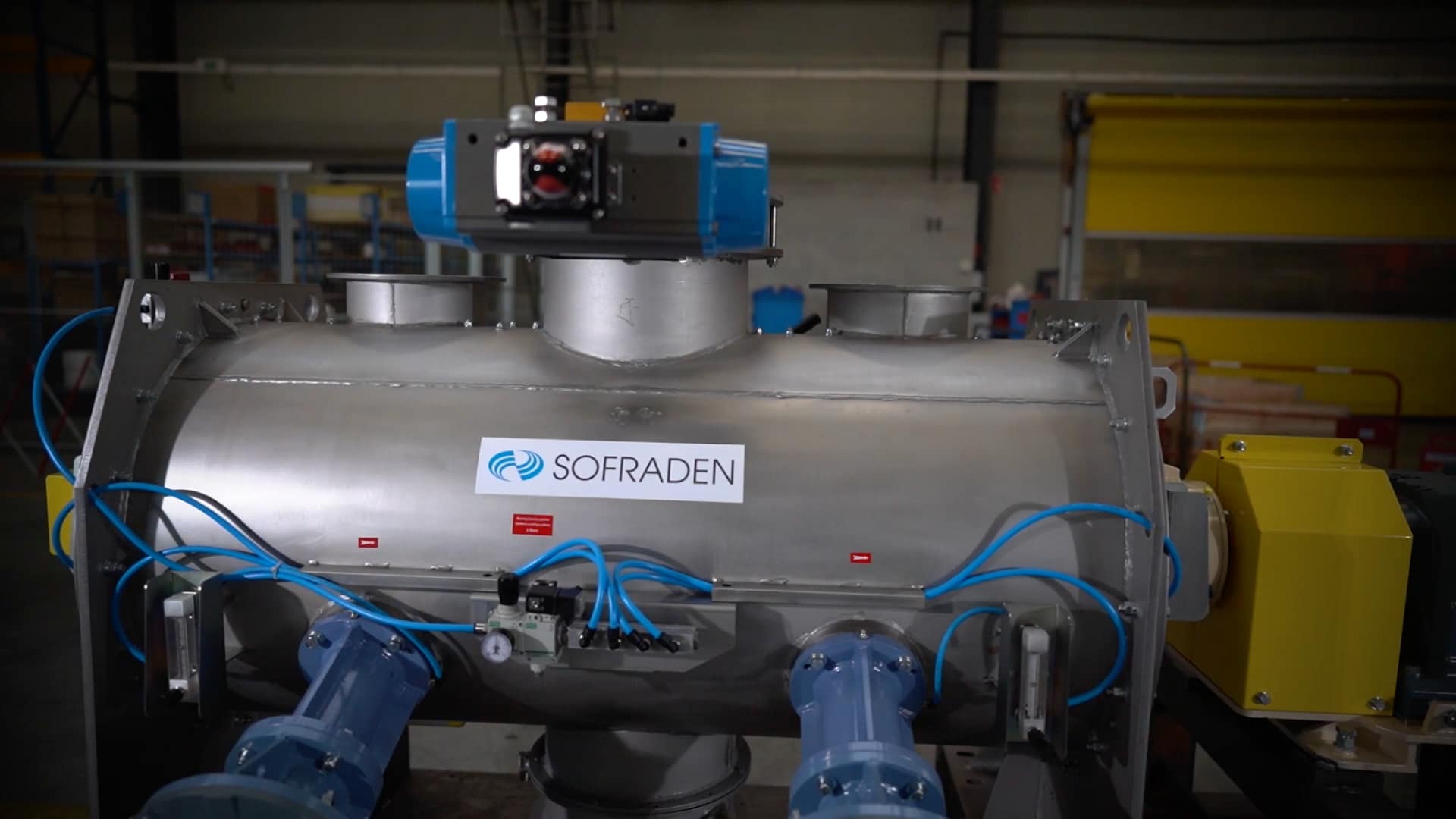

Le centre d'essai SOFRADEN met ses mélangeurs à votre disposition pour valider vos applications.

Gratuit

un audit d'inspection de votre mélangeur

La qualité de vos mélanges n'est plus celle attendue ? Votre coût de maintenance augmente ?

SOFRADEN vous aide à prendre les bonnes décisions en vous proposant un audit gratuit et complet de votre machine et de votre installation de mélange ?

Cas clients

BLOG

Le nettoyage du mélangeur industriel est une étape critique pour toutes les entreprises qui produisent avec des contraintes de contaminations croisées ou de haute qualité. Le système de nettoyage en place NEP permet d’optimiser cette phase et donc d’augmenter sa productivité.

En raison de l’abrasivité des produits, les mélangeurs industriels sont sujets à une usure importante qui peut affecter leur efficacité et leur durabilité. Pour cette raison, des protections anti-abrasion sont installées pour prolonger la durée de vie des mélangeurs industriels.